Welcome To BEA

BT100F-WL

Features

◇ low flow liquid transfer:can transport liquid by microliter.

◇ back suction :on dispensing mode .the motorcan run reversely by a specific angle therefore, it can provent incendent droping

◇ operation mode:membrane key and rotary knob to set paremeter and operate.

◇ various control way:membrane key,external control,RS485 communication,wireless remote control

◇ display:LCD screen show all information and parameters

◇ max speed key:flush and empty the tubing promptly

◇ memory function:memorize the inputed parameters and working status automatically.

◇ calibration:can calibrate the flow rate and dispensing volume ,therefore the precision is improved.

◇ communication:RS485 and wireless remote control

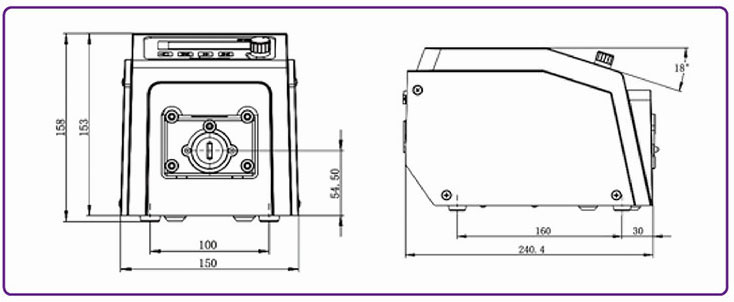

Dimensions

Technical paraeters

◇ motor speed:0.1-100rpm,reversible

◇ speed resolution:0.1rpm

◇ control mode:rotary knob with membrane key,external analog control signals

RS485 communication with PC and wireless control

◇ Display:LCD screen

◇ volume range of dispensing:0.01ml – 9.99L

◇ volume calibration of dispensing :input the actual volume data by test to calibrate automatically

◇ dispensing times:1-9999 times ,“0”:unlimited recycle mode

◇ external control function:start/stop、cw/ccw direction ,flow rate(4-20mA、0-5V、0-10V、0-10KHZ are optional)

◇ signal output of motor speed status:0-10kHz linear correspond to 0.1-100rpm

◇ signal output of start/stop:OC gate signal output

◇ signal output of cw/ccw direction::OC gate signal output

◇ communication interface:RS485

◇ power off memory function:work as the previous status after re-powered

◇ max speed key:effect prompt filling and emptying .

◇ measurements:285 × 207×180(LXWXH)mm

◇ suitable temperature:0℃-40℃

◇ suitable humidity:relative humidity< 80%

◇ IP rating:IP31

◇ weight:3.8kg

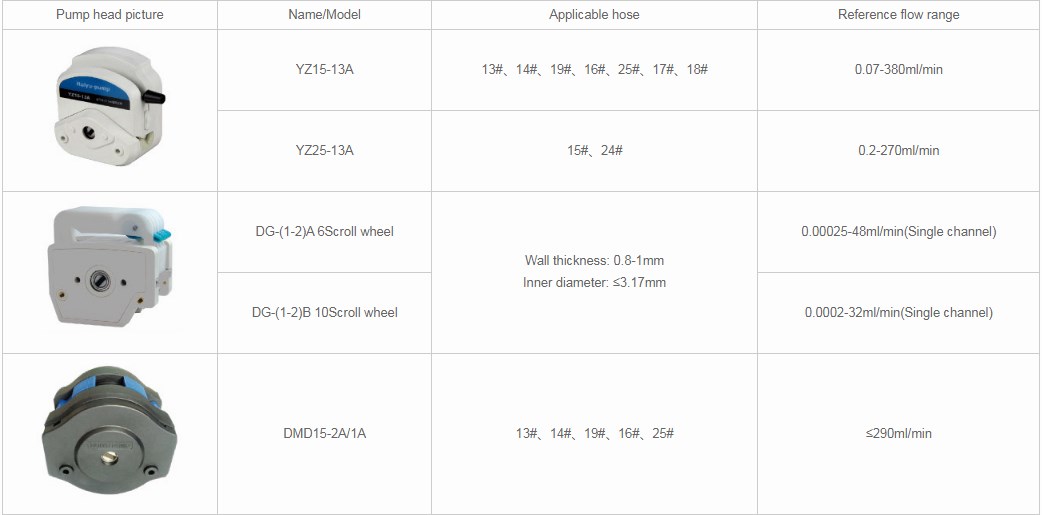

Products categories

Why Choose Us

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..